In modern manufacturing, CNC pallet systems have revolutionized production efficiency by reducing downtime and improving workflow. These automated workholding solutions allow manufacturers to load, unload, and machine parts with minimal manual intervention, making them ideal for high-volume production and lights-out machining.

In this guide, we’ll explore the key benefits of CNC pallet systems, how they work, and why they’re a game-changer for precision machining.

What Is a CNC Pallet System?

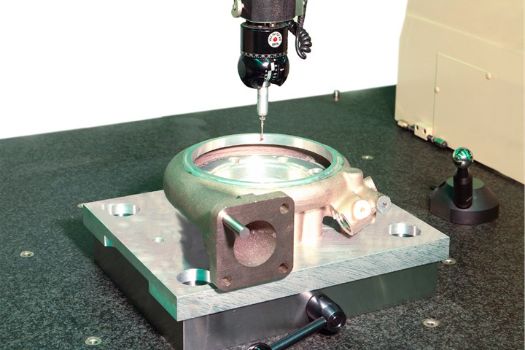

A CNC pallet system consists of multiple pallets (workholding platforms) that can be automatically swapped in and out of a machining center. Operators can load raw materials onto one pallet while the machine processes another, drastically reducing idle time.

Common types include:

-

Manual Pallet Changers – Operator swaps pallets between cycles.

-

Automatic Pallet Changers (APC) – Robotic or hydraulic pallet swapping.

-

Rotary Pallet Systems – Multiple pallets on a rotating carousel.

Top 7 Benefits of CNC Pallet Systems

1. Reduced Machine Downtime

-

Operators can load/unload parts offline while the CNC machine continues cutting.

-

Eliminates waiting time between jobs, increasing spindle utilization by up to 90%.

2. Increased Production Efficiency

-

Ideal for high-volume production where multiple parts need machining.

-

Enables batch processing with minimal setup changes.

3. Improved Consistency & Accuracy

-

Pallet repeatability ensures precise alignment (±0.0005″ or better).

-

Reduces human error in part positioning.

4. Enables Lights-Out Machining

-

With automatic pallet changers (APCs), machines can run unattended overnight.

-

Maximizes productivity for 24/7 operations.

5. Flexible Manufacturing

-

Quick changeovers between different jobs.

-

Supports mixed-part production without lengthy setups.

6. Better Workflow & Labor Savings

-

Reduces manual handling and operator fatigue.

-

One operator can manage multiple machines.

7. Cost-Effective for Long Runs

-

Higher throughput means lower cost per part.

-

Faster ROI for medium to large production batches.

Industries That Benefit from CNC Pallet Systems

✔ Aerospace – High-precision, complex parts

✔ Automotive – Mass production of engine components

✔ Medical Manufacturing – Tight-tolerance implants & instruments

✔ Mold & Die Making – Reduced setup time for large molds

✔ General Machining – Job shops with diverse part requirements

Choosing the Right Pallet System

When selecting a CNC pallet system, consider:

-

Number of pallets needed (2-pallet vs. multi-pallet carousels)

-

Load capacity (weight & size of workpieces)

-

Automation level (manual, semi-auto, or full APC)

-

Repeatability requirements (for high-precision industries)

Conclusion

CNC pallet systems offer unmatched efficiency, accuracy, and productivity for machining operations. By reducing downtime, enabling lights-out machining, and improving workflow, they help manufacturers cut costs and boost output.

Interested in integrating a pallet system into your CNC workflow? Contact us for expert advice and solutions tailored to your needs!