Custom metal parts solutions are our speciality at DO Machining. Through the use of the most available technology and personalized service, DO Machining is an industry leader in CNC machining, Metal Stamping and Metal fabrication.

At DO Machining, we help you get your project completed fast according to your good designs and relevant information. The attractiveness of the exterior of the part, the quality appearance of the surface, and the pleasantness of the feel are extremely important factors for having the customer choose your product over another. A creative surface finish can make your product stand out in a crowd.

What’re the Surface Treatment Finishing services available at DO Machining ?

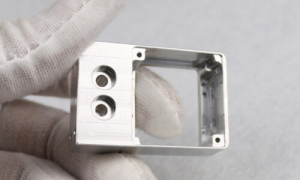

Machine Finish – Cutter marks from the CNC Machining process will be present. It suits to all common materials, such aluminum, steel, brass, stainless steel, titanium, plastics, etc.

Anodizing – The process by which aluminum and its alloys form an anodized film on aluminum products (anodes) under the action of impressed current under the appropriate electrolyte and specific process conditions.

What’s the function of Anodizing?

1. Improve the abrasion resistance of aluminum;

2. Increased corrosion resistance;

3. Insulate aluminum.

Sand Blasting – The process of cleaning and coarsening the substrate surface by the impact of high-speed sand flow. Mainly suits to common metals and plastics, such as aluminum, steel, stainless steel, brass, ABS, etc.

What’s the function of Sand Blasting?

1. Improve the mechanical properties of workpiece surface;

2. Improve the fatigue resistance of workpiece;

3. Increases the adhesion between it and the coating.

Polishing – The use of mechanical, chemical or electrochemical action, the workpiece surface roughness reduction, in order to obtain a bright, flat surface processing method. The use of polishing tools and abrasive particles or other polishing media on the workpiece surface modification processing. Suits to mainly metals, such as aluminum, steel, stainless steel, brass, etc.

What’s the function of Polishing?

1. Remove surface scratches and burrs;

2. Improve workpiece surface finish;

Powder coating – To spray the powder coating onto the surface of the workpiece with powder spraying equipment. Under the action of static electricity, the powder will evenly adsorb on the surface of the workpiece and form a powder coating.Powder coating after high temperature baking leveling solidification into different effects of the final coating. Suits to mainly metals, such as aluminum, steel, stainless steel, brass, etc.

What’s the function of Powder coating?

1. Reduce pollution to the environment;

2. Save surface treatment cost;

3. Energy saving

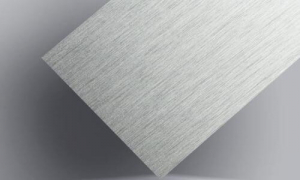

Brushing – Is a kind of surface treatment method which forms lines on workpiece surface by grinding products and plays a decorative effect. Suits to mainly metals, such as aluminum, steel, stainless steel, brass, titanium, etc.

What’s the function of Brushing?

1. Make the metal surface obtain non-mirror metallic luster;

2. Cover up the production of mechanical lines and mold defects;

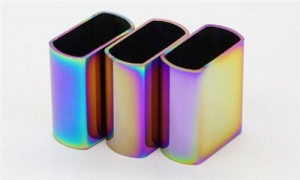

Electroplating – Is the process of plating a thin layer of other metals or alloys on the surface of some metals by using the principle of electrolysis. Common electroplating types including: Zinc plating, Nickel plating, Chrome plating, Gold plating, Silver plating, etc. Suits to mainly metals, such as aluminum, steel, stainless steel, brass, titanium, etc.

What’s the function of Electroplating?

1. Prevent metal oxidation;

2. Improve wear resistance, electrical conductivity, reflection, corrosion resistance;

3. Make the surface beautiful.

If you can’t find the Surface Finish you’re looking for, or have any comments or requests, please CONTACT us, and we’ll respond promptly.