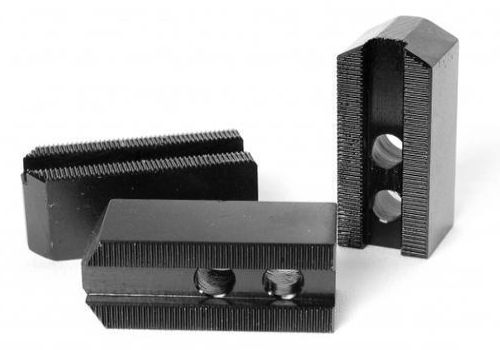

Soft jaws are one of the most versatile workholding solutions in CNC machining, offering customizable, repeatable clamping for irregular or delicate parts. Unlike standard hard jaws, soft jaws are machinable, allowing you to create perfectly contoured grips for unique workpiece shapes.

In this guide, we’ll explain what soft jaws are, how to use them effectively, and best practices to maximize their benefits in your CNC operations.

What Are Soft Jaws?

Soft jaws are replaceable, machinable vise jaws typically made from aluminum, mild steel, or plastic. They can be custom-cut to match the exact profile of your workpiece, providing:

✔ Better grip – Prevents part movement during machining

✔ Higher repeatability – Ideal for batch production

✔ Reduced part deformation – Gentle clamping for delicate materials

Types of Soft Jaws

| Type | Material | Best For |

|---|---|---|

| Aluminum Soft Jaws | 6061 or 7075 Aluminum | Light to medium-duty clamping |

| Steel Soft Jaws | Mild Steel (A36) | Heavy-duty machining |

| Plastic/Nylon Soft Jaws | Delrin, UHMW | Non-marring for finished surfaces |

| Step Jaws | Aluminum/Steel | Holding round or irregular shapes |

How to Use Soft Jaws in CNC Machining

Step 1: Select the Right Material

-

Aluminum – Best for general-purpose use (light cuts, fast machining).

-

Steel – Required for high-force operations (heavy milling, turning).

-

Plastic – Protects finished surfaces from scratches.

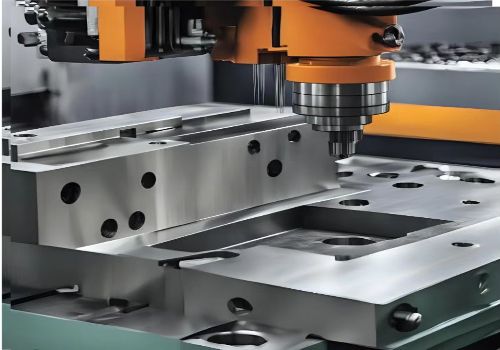

Step 2: Machine the Jaw Profile

-

Mount the soft jaws in your CNC vise.

-

Bore or mill a cavity matching your part’s shape.

-

Add serrations or grooves (for better grip on smooth surfaces).

Pro Tip: Use a pre-finished workpiece as a reference for perfect contouring.

Step 3: Secure the Workpiece

-

Apply even clamping pressure to avoid distortion.

-

For round parts, use V-grooves or step jaws for better contact.

Step 4: Verify Stability

-

Perform a light test cut to check for movement.

-

Use an indicator to confirm part alignment.

Advantages of Soft Jaws

✅ Custom Fit – Perfectly matches part geometry.

✅ Repeatability – Ideal for batch production.

✅ Gentle on Parts – Reduces marks and deformation.

✅ Cost-Effective – Cheaper than custom fixtures.

Common Mistakes to Avoid

❌ Over-tightening – Can distort thin-walled parts.

❌ Poor Jaw Machining – Inaccurate profiles lead to slippage.

❌ Using Worn-Out Jaws – Replace if grip weakens.

❌ Ignoring Chip Buildup – Clean jaws regularly.

Best Applications for Soft Jaws

✔ Prototyping – Quick adaptation for new designs.

✔ Low-Volume Production – Repeatable setups.

✔ Delicate Parts – Avoids crushing with even pressure.

✔ Oddly Shaped Workpieces – Custom profiles for irregular geometries.

Conclusion

Soft jaws are a game-changer for CNC machining, offering flexibility, precision, and repeatability. By machining custom profiles and following best practices, you can improve part quality, reduce setup time, and minimize waste.

Need high-quality soft jaws for your CNC vise? Browse our selection or contact our experts for recommendations!