How to find the center coordinates of the circle on CNC machining center? It is one of the problems faced by many newcomers who are new to CNC machining centers. Today we will introduce how to find the center coordinates of a circle on a machining center.

1. How to find the center coordinates of the circleon CNC machining center?

A. Put the dial indicator on the main shaft and move it to the approximate locationof the circle center, then manually turn the main shaft to see which side of x and y is pressed more. Then manually turn the spindle to debug slowly until the three points are in the same position. This will get better after you get used to it slowly.

B. Install a drill bit with the tip roughly aligned with the center of the circle. Lift the Z-axis, disassemble the knife, the meter seat is sucked on the spindle (the position of the knife edge), the dial indicator is against the surface of the workpiece. Then manually rotate the spindle, observe the dial indicator, which direction pressure meter more, manually move to the negative direction.

C. Now there is a coaxial deviation alignment device. As long as the instrument is clamped on the main shaft, the main shaft rotates twice, and the main shaft moves once, the XY between the main shaft axis and the workpiece axis can be displayed on the display screen. For the deviation size under the coordinates, just shake the main shaft according to the size, which is very convenient.

2. Learn about the center coordinates of CNC machining center

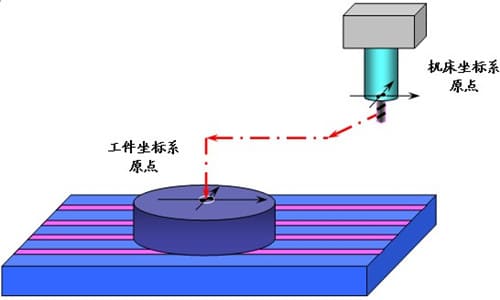

In order to describe the motion of the machine tool during CNC programming, simplify the method of programming and ensure the interchangeability of recorded data, the coordinate system and movement direction of the CNC machine tool have been standardized, and ISO has formulated a naming standard. Machine Coordinate System is a Cartesian coordinate system consisting of X, Y, and Z axes established by the machine tool origin O as the origin of the coordinate system and following the right-hand Cartesian Cartesian coordinate system. The machine tool coordinate system is the basic coordinate system used to determine the workpiece coordinate system. It is an inherent coordinate system on the machine tool and has a fixed coordinate origin.

As a professional CNC machining manufacturer, DO Machining not only produce metal parts, but plastic and wood parts are also available.

Please visit our CAPABILITIES and what PRODUCTS we did.

CNC machining service is the core business of DO Machining, from protptyes to bulk production, our professional 3/4/5 aixs CNC machining centers, CNC turning equipments, CNC turning-milling equipments, CNC grinding machines etc., are operated by well trained manufacturing engineers to meet the demands from global 1000+ customers in 30+ industries.

CNC Machining can be done starting with blanks produced from standard bar stock or one of DO Machining other manufacturing processes.

Contact us to see how we can provide overall value to your CNC machining needs.