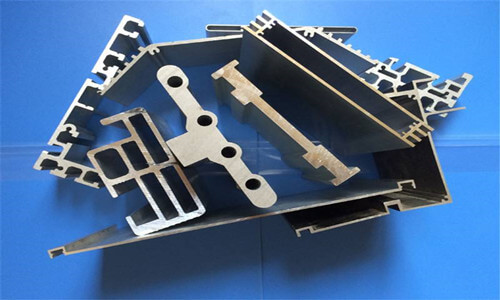

Both burrs and shock marks are common defects in the extrusion of aluminum profiles. Burr is the residual particles and very fine metal particles appear on the surface of metal parts, and shock mark is the relatively concentrated particles on the surface of the profile. The causes of burrs and shocks are multifaceted, and the influence of the extrusion die is a very important aspect. Let’s take a look at what problems occur in the die, which can cause burrs and shock marks on the workpiece, and how to solve this problem.

Elastic deformation of the die

Theoretically, the working zone in the die processing is parallel to the extrusion direction. However, in the actual production process, when the die is squeezed, it is in a state of high temperature and high pressure, and the working belt is often deformed into a trumpet shape, and only the cutting edge portion of the working belt can contact the sticky aluminum formed by the profile to form a similar structure to tool tumor. During the entire process of forming the aluminum, the “tool tumor” is continuously taken out by the profile and adhered to the surface of the profile, thus forming burrs and shock marks.

Die empty tool position is too shallow

If the empty position of the die is too shallow, it will cause the sticky aluminum to gradually increase and form burrs; and the sticky aluminum that cannot be taken out by the profile and the die does not fall off when it rebounds instantly will form defects such as bright bands and coarse grain.

Solutions to burrs and shocks caused by die

The first is to select the appropriate die size according to the circumscribed circle diameter, wall thickness, single weight, extrusion ratio and other conditions of the profile. It is necessary to have the appropriate number of holes and the model, which is beneficial to reduce the conditions for forming the sticky aluminum and reduce the probability of forming “burr” or “shock marks”.

The second is to increase the strength of the die and reduce the elastic deformation of the die. In actual production, the greater the amount of elastic deformation of the die, the greater the possibility of forming burrs and shock marks. Such as porous dies and long cantilever, etc., due to the low degree of light, are the “hardest hit areas” that produce burrs and shock marks. When designing the die, try to choose the best parameter value and increase the strength of the die. In addition to considering the length of the working belt, the form of the neck, the form of the welding chamber, the amount of empty knives, and the size of the split hole, the thickness of the front mat and the form of the inner hole are also required to form an effective support for the die.

The third is to reduce the metal flow dead zone of the die. This requires that in the manufacturing process, the excessive surface of the inner cavity and the excessive surface of the R position should be smooth, and the surface of the metal flow should reduce the friction coefficient as far as possible.

The fourth is to adjust the roughness of the die surface, the parallelism of the working belt, the hardness of the surface of the working belt, etc., because these are closely related to the generation of burrs and shock marks. After the adjustment, sandblasting and polishing should also be carried out to obtain sufficient parallelism, and then nitriding treatment to further improve the smoothness.

Finally, before the die is mounted, a layer of rust inhibitor is sprayed on the mating surface of the die part and the welding chamber. The bolt must be locked when the mold is installed.