Generally when machining, the workpiece size usually has specific parameter requirements, and even some requirements are very strict. However the unstable workpiece size not only reduces the order qualification rate, but also causes damage to the equipment.

How to solve the problem of CNC machining unstable workpiece size?

Judgment and repair of CNC machining unstable workpiece size.

1. Accurate workpiece size and poor surface finish

Causes of failure: The tool tip is damaged and not sharp; the machine generates resonance and is not stable; the machine has a creep phenomenon; the processing technology is not good.

Solution: If the tool is not sharp after being worn or damaged, re-sharpen or select a better tool to re-set the tool; if the machine has resonance or the placement is not stable, adjust the level, lay the foundation, and stabilize it; The cause reason of creep phenomenon is that the plate guide rail wears a lot, and the screw balls wear or become loose. The machine should pay attention to maintenance. Before or after work, clean the metal wire and add lubricant in time to reduce friction.

2.The phenomenon of taper size of the workpiece

Causes of failure: The level of machine tool placement is not adjusted properly, one high and one low, resulting in uneven placement; when turning the long axis, the processing material is relatively hard, the tool cuts deeper, causing cutter back-off phenomenon; Tailstock thimble is not centered with spindle.

Solution: use a spirit level to adjust the level of the machine tool, fix the machine tool to improve its toughness; choose a reasonable process and appropriate cutting feed to avoid cutter back-off phenomenon; adjust the tailstock.

3. The driver’s phase light is normal, and the size of the processed workpiece is large and small

Causes of failure: Long-term high-speed operation of the carriage of the machine tool results in wear of the screw rod and bearings; the repeated positioning accuracy of the tool post will deviate during long-term use; the carriage can accurately return to the starting point of the machining every time, but the size of the workpiece remains unchanged. This phenomenon is generally caused by the main shaft, and the high-speed rotation of the main shaft causes serious bearing wear and changes in machining sizes.

Solution: Use a dial indicator to lean against the bottom of the tool holder, and at the same time edit a fixed cycle program through the system to check the repeat positioning accuracy of the carriage, adjust the screw clearance, and replace the bearing; use the dial indicator to check the repeat positioning accuracy of the tool holder. Adjust the machine or replace the tool holder; use a dial indicator to check whether the workpiece is accurately returned to the starting point of the program. If possible, repair the spindle and replace the bearing.

4. The workpiece size differs from the actual size by a few millimeters, or there is a large change in an axial direction

Cause of failure: The speed of rapid positioning is too fast, and the drive and motor cannot respond in time; the mechanical carriage screw and bearing are too tight after long-term friction loss; the tool holder is too loose after changing the tool; the edited program is wrong; the system’s electronic gear ratio or step angle is set incorrectly.

Solution: The fast positioning speed is too fast, adjust the speed of GO appropriately, the CNC machining center cutting acceleration and deceleration speed and time make the driver and motor work normally at the rated operating frequency; after the machine tool wears out, the carriage, screw and the bearing are too tight, it must be readjusted and repaired; the tool holder is too loose after changing the tool, check whether the tool holder reverse time is satisfied, check whether the turbine worm inside the tool holder is worn, whether the gap is too large, whether the installation is too loose, etc .; If it is caused by a program, you must modify the program, improve it according to the requirements of the workpiece drawing, choose a reasonable processing technology, and edit the correct program according to the instructions; if you find that the size deviation is too large, check whether the system parameters are set properly, especially whether the electronic gear and the step angle are damaged, this phenomenon can be measured by dialing a dial indicator.

5. The arc effect is not ideal, and the size is not in place

Cause of failure: resonance caused by overlapping vibration frequency; processing technology; parameter setting is unreasonable, feed speed is too large, making arc processing out of step; loosening caused by large screw clearance or out of step caused by too tight screw; timing belt abrasion

Solution: find out the parts that generate resonance, change their frequency, and avoid resonance; consider the processing technology of the workpiece material and formulate the program reasonably; for stepper motors, the processing rate F cannot be set too large; the install and place machine firmly; replace the timing belt.

6. Occasionally the workpiece is out of tolerance during mass production

Cause of failure: Careful inspection of the tooling fixture must be taken into consideration, and the operator’s operation method and the reliability of the clamping must be taken into account. Due to the dimensional changes caused by the clamping, the tooling must be improved so that workers can avoid misjudgment as much as possible due to human negligence; the CNC system may Interference pulses are automatically generated when the external power source fluctuates or is disturbed. The pulses are transmitted to the driver to cause the driver to accept extra pulses. Learn to master the law and try to adopt some anti-interference measures, such as: strong electric field interference. The strong cable is isolated from the signal line of the weak signal. Add anti-interference absorption capacitors and shielded wires. In addition, check whether the ground wire is connected firmly and the ground contact is nearest. Take all anti-interference measures to avoid system interference.

7. There is a change in one procedure of machining workpiece, and the sizes s of other processes are accurate.

Reason for failure: whether the parameters of the program are reasonable, whether they are within the predetermined trajectory, and whether the programming format meets the requirements of the instruction manual.

Solution: When the thread block is chaotic and the pitch is not correct, the peripheral configuration (encoder) of the thread and the objective factors of the function are immediately associated.

8. Each process of the workpiece has an increasing or decreasing phenomenon

Causes of failure: incorrect programming; system parameter settings are unreasonable; configuration settings are incorrect; Mechanical transmission components have regular and periodic changes in fault

Solution: Check whether the instructions used by the program follow the required trajectory specified in the instruction manual. You can judge by dialing the dial indicator, positioning the dial indicator at the starting point of the program, and letting the carriage return to the starting point after the program is over. You can observe the results and master its laws; check whether the system parameters are set properly; whether the relevant machine tool configuration meets the requirements on the calculation parameters of the connection calculation and whether the pulse equivalent is accurate; check whether the transmission part of the machine tool is damaged and the gear coupling is uniform , Check if there are periodic and regular failure phenomena.

9. Unstable size change caused by the system

Causes of failure: The system parameters are set unreasonably; the operating voltage is unstable; the system is out of step due to external interference; capacitors have been added, but the impedance between the system and the driver does not match, resulting in the loss of useful signals; the signal between the system and the driver transmission is abnormal; system is damaged or internal failure.

Solution: whether the speed and acceleration time are too large, whether the spindle speed and cutting speed are reasonable, whether the operator’s parameter modification causes the system performance to change; install voltage stabilization equipment; choose an appropriate capacitor type; check the signal between the system and the driver whether the connection line is shielded and the connection is reliable. Check whether the system pulse occurrence signal is lost or increased.

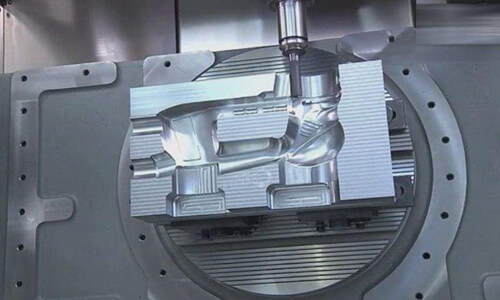

CNC machining service is the core business of DO Machining, from protptyes to bulk production, our professional 3/4/5 aixs CNC machining centers, CNC turning equipments, CNC turning-milling equipments, CNC grinding machines etc., are operated by well trained manufacturing engineers to meet the demands from global 1000+ customers in 30+ industries.

CNC Machining can be done starting with blanks produced from standard bar stock or one of DO Machining other manufacturing processes.

Contact us to see how we can provide overall value to your CNC machining needs.