Rapid prototype means that on the premise of no mold opened, according to the product appearance drawings or structural drawings to make one or several functional models to check the appearance or structural rationality.

Usually, newly developed or designed products need to do rapid prototype, it is the first step to verify the feasibility of the product. And it is the most direct and effective way to find the design of the product defects and deficiencies, so that the defects can be targeted improved.

Rapid prototype types

Classified by means of production:

It has handmade prototype and CNC prototype

Handmade prototype: The main workload is done by hand. Handmade prototype has abs prototype and clay prototype two classification.

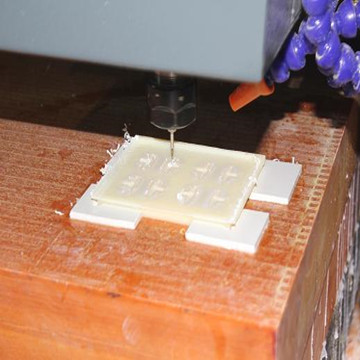

CNC prototype: The main workload is done by CNC machine. According to the different equipment used, it can be divided into laser rapid prototype and CNC prototype and 3D printing.

Classified by means of materials used:

According to materials used, it can be divided into plastic prototype, silicone prototype and metal prototype

Plastic prototype: the prototype raw material is plastic, mainly used for televisions, monitors, telephones and so on.

Silicone prototype: the prototype raw material is silicone, mainly to show the shape of the product design, such as cars, mobile phones, toys, handicrafts, daily necessities, etc.

Metal prototype: the prototype raw material metal, mainly used for some high-end products, such as laptop, advanced player, MP3 players and so on.

Rapid prototype usage

Test the design

Prototype is not only visible, but also can be touched. You can check if the appearance is the same as you imagined. So rapid prototype production in the new product development is essential.

Test structure design

Because the prototype can be assembled, so it can be intuitive to reflect if the structure is rational or not.

Avoid the risk of direct mold

As the cost of mold manufacturing is high, if found unreasonable or other problems during opening mold process, the loss can be imagined. However prototype production can avoid such losses, reduce the risk of opening mold.

Products are available in advance

Due to the advance of rapid prototype production, you can use the prototype for product promotion before the mold is developed, even the preparation for pre-sale and production, then you can occupy the market early.

Note: Above information is just for reference only.

We offer CNC Machining, Metal Stamping, Metal fabrication services, if you have project need support, contact us today.