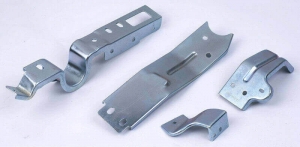

The stamping process is a process in which the sheet is separated or shaped to obtain a part. Stamping is a metal processing method, which is based on the metal plastic deformation on the basis of the use of mold and stamping equipment to apply pressure on the sheet, the sheet material will has plastic deformation or separation, then get the part needed.

Stamping process characteristics

1.Stamping is a high production efficiency, low material consumption processing methods. The stamping process is suitable for the production of larger batches of parts, facilitates mechanization and automation, and has high productivity. At the same time, stamping can not only strive to produce less waste and no waste, but even in some cases Angle more than expected, can also be fully utilized.

2.Easy to operate, do not need higher level of skills.

3.Stamped parts generally do not need to be machined, it has high dimensional accuracy.

4.Stamping parts have a good interchangeability. Stamping processing stability is better, the same batch of stamping parts can be used interchangeably, does not affect the assembly and product performance.

5.As the stamping parts produced with sheet metal, the surface quality is nice, which will provide a convenient condition for the follow-up surface treatment processes (such as plating, painting).

6.Stamping can get high strength, high stiffness and light weight parts.

7.The stamping parts produced in mass with the mold are inexpensive.

8.Stamping can create complex shape parts which other metal processing methods difficult to process.

Note: Above information is just for reference only.

We offer CNC Machining, Metal Stamping, Metal fabrication services, if you have project need support, contact us today.