Introduction

When it comes to precision CNC machining, your vise choice can make or break part accuracy. A high-quality CNC vise ensures tight tolerances (±0.0005″ or better), minimal deflection, and repeatable results. But with so many options—from hydraulic to modular vises—how do you choose the right one?

In this guide, we’ll break down the top CNC vises for precision work, compare their features, and provide expert recommendations for your machining needs.

Key Features of a Precision CNC Vise

Before selecting a vise, consider these critical factors:

✔ Repeatability – Consistent clamping accuracy

✔ Rigidity – Resists vibration and deflection

✔ Clamping Force – Holds parts securely without distortion

✔ Ease of Use – Quick setup for efficiency

✔ Durability – Long-lasting performance

Top 5 CNC Vises for Precision Work

1. Kurt DX6 AngLock Vise

-

Best for: General high-precision milling

-

Key Features:

-

Hardened steel construction

-

±0.0002″ repeatability

-

Dual clamping force (12,000 lbs)

-

-

Pros: Industry standard, excellent grip

-

Cons: Heavy, requires proper mounting

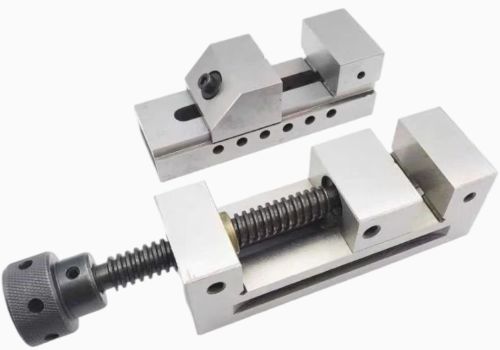

2. Orange Vise Tormach TTS

-

Best for: Small CNC mills and prototyping

-

Key Features:

-

Modular design (quick jaw changes)

-

Low-profile for better tool access

-

±0.0005″ repeatability

-

-

Pros: Lightweight, versatile

-

Cons: Lower clamping force than Kurt

3. Chick One-Lok Vise

-

Best for: High-speed, high-volume production

-

Key Features:

-

Single-action clamping

-

0.0003″ repeatability

-

Compatible with automation

-

-

Pros: Fast setup, minimal deflection

-

Cons: Expensive

4. Röhm Supra CNC Vise

-

Best for: Heavy-duty machining

-

Key Features:

-

18,000 lbs clamping force

-

Precision-ground base (±0.0004″)

-

Anti-lift design

-

-

Pros: Extreme rigidity, German engineering

-

Cons: Bulky for small mills

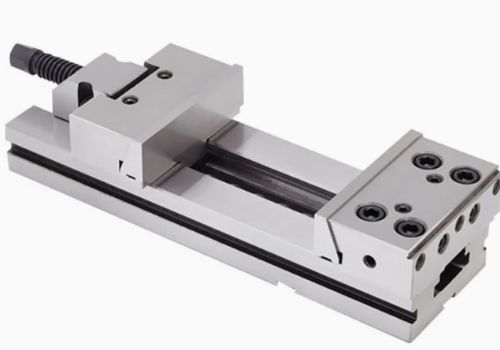

5. Glacern GSV-440

-

Best for: Budget precision work

-

Key Features:

-

Hardened steel, ground surfaces

-

±0.0005″ repeatability

-

Affordable alternative to Kurt

-

-

Pros: Great value, good for beginners

-

Cons: Not as durable as premium brands

CNC Vise Comparison Table

| Vise Model | Repeatability | Clamping Force | Best Use Case | Price Range |

|---|---|---|---|---|

| Kurt DX6 | ±0.0002″ | 12,000 lbs | General precision | $$$ |

| Orange Vise TTS | ±0.0005″ | 6,000 lbs | Prototyping | $$ |

| Chick One-Lok | ±0.0003″ | 10,000 lbs | High-volume | $$$$ |

| Röhm Supra | ±0.0004″ | 18,000 lbs | Heavy-duty | $$$$ |

| Glacern GSV-440 | ±0.0005″ | 8,000 lbs | Budget precision | $ |

How to Maximize Precision with Your CNC Vise

-

Use Soft Jaws – Machine custom contours for better grip.

-

Properly Torque Mounting Bolts – Prevents shifting during cuts.

-

Check Parallelism – Ensure vise alignment with an indicator.

-

Avoid Overhang – Keep parts fully supported.

-

Regular Maintenance – Clean and lubricate moving parts.

When to Upgrade Your CNC Vise

-

You’re struggling to hold ±0.001″ tolerances

-

Experiencing part slippage or chatter

-

Needing faster setups for production

-

Switching to 5-axis or high-speed machining

Conclusion

For precision CNC work, investing in a high-repeatability vise like the Kurt DX6 or Chick One-Lok pays off in accuracy, efficiency, and reduced scrap rates. If you’re on a budget, the Glacern GSV-440 offers solid performance at a lower cost.

Need help choosing the right vise? Contact our experts for personalized recommendations!