Introduction

As manufacturers face increasing pressure to reduce environmental impact, sustainable CNC machining has become a competitive necessity. Choosing eco-friendly materials can lower carbon footprints by 30-60% while maintaining performance. But which materials deliver both planetary and machining benefits?

This guide explores the top sustainable materials for CNC, their properties, applications, and real-world environmental advantages.

Key Sustainability Criteria for CNC Materials

When evaluating materials, consider:

-

Recyclability: Can be reused without quality loss

-

Renewable Sourcing: Made from bio-based resources

-

Low Embodied Energy: Minimal energy required for production

-

End-of-Life Impact: Biodegradable or safely recyclable

-

Machinability: Reduces waste during processing

Top 8 Sustainable Materials for CNC Machining

1. Recycled Aluminum (6061-R)

-

Sustainability Benefits:

✔ 95% less energy than virgin aluminum

✔ Infinitely recyclable without degradation -

Machining Notes:

Identical properties to virgin 6061

Excellent for aerospace, automotive -

Carbon Reduction: 8.6 kg CO2/kg vs. 16.7 kg (virgin)

2. Bio-Polymers (PHA/PHB)

-

Sustainability Benefits:

✔ Marine-biodegradable (6-24 months)

✔ Made from plant oils or bacteria -

Machining Notes:

Similar to ABS but zero toxic fumes

Ideal for medical/disposable prototypes -

Innovator: Danimer Scientific (FDA-approved)

3. Recycled Titanium (Ti6Al4V-R)

-

Sustainability Benefits:

✔ 60% less energy than virgin titanium

✔ Recycled from aerospace scrap -

Machining Notes:

Requires carbide tools, slower speeds

Perfect for high-strength implants -

Cost Impact: 20-30% cheaper than virgin Ti

4. Bamboo Fiber Composites

-

Sustainability Benefits:

✔ Carbon-negative material

✔ Rapidly renewable (harvest in 3-5 years) -

Machining Notes:

Use sharp carbide tools (50-60 HRC)

Great for consumer electronics housings -

Strength: Comparable to oak at 1/3 weight

5. Recycled Polypropylene (rPP)

-

Sustainability Benefits:

✔ Lowest CO2 footprint of recycled plastics

✔ Food-safe after processing -

Machining Notes:

Minimal coolant needed

Used for food handling components -

Recycling Rate: 98% less waste than virgin PP

6. Cast Iron (Recycled)

-

Sustainability Benefits:

✔ 90%+ recycled content

✔ Lasts decades with proper maintenance -

Machining Notes:

Excellent vibration damping

Ideal for machine bases/fixtures -

Lifecycle: 100% recyclable at end-of-life

7. Mycelium Composites

-

Sustainability Benefits:

✔ Grown from agricultural waste

✔ Biodegrades in 45 days -

Machining Notes:

Low-speed machining only

Temporary fixtures/packaging -

Pioneer: Ecovative Design

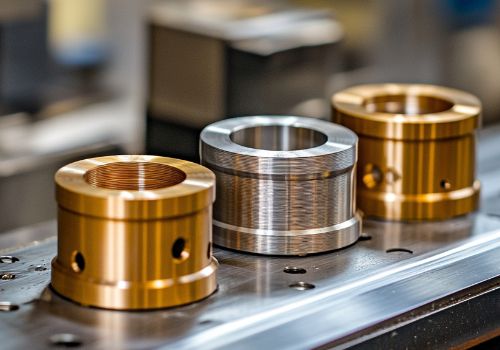

8. Recycled Brass (CZ121)

-

Sustainability Benefits:

✔ 85% less energy than virgin brass

✔ Recycled from plumbing/electrical waste -

Machining Notes:

Superior chip formation

Best for precision valves/fittings -

Recycling Loop: Infinite reuse possible

Sustainability Comparison Table

| Material | Recycled Content | CO2/kg (kg) | Machinability | Best Applications |

|---|---|---|---|---|

| Recycled Aluminum | 100% | 8.6 | ★★★★★ | Frames, enclosures |

| PHA Biopolymer | 0% (plant-based) | 1.2 | ★★★☆☆ | Disposable medical |

| Recycled Titanium | 90%+ | 18.1 | ★★★☆☆ | Aerospace, implants |

| Bamboo Composite | 60-80% | -0.5* | ★★☆☆☆ | Consumer goods |

| Recycled PP | 100% | 1.8 | ★★★★☆ | Food-safe parts |

| *Carbon-negative due to sequestration |

How to Source Sustainable Materials

-

Certifications to Look For:

-

ASI (Aluminium Stewardship Initiative)

-

Cradle to Cradle Certified™

-

USDA BioPreferred

-

-

Top North American Suppliers:

-

Matalco (Recycled Aluminum)

-

Green Dot Bioplastics (PHA Compounds)

-

Sintavia (Recycled Titanium)

-

Design Tips for Sustainable CNC

-

Minimize Material Volume: Use topology optimization

-

Standardize Stock Sizes: Reduce cut-off waste

-

Avoid Mixed Materials: Simplifies recycling

-

Design for Disassembly: Facilitates material recovery

Case Study: Electric Scooter Manufacturer

Challenge: Reduce 28% scrap rate on aluminum frames

Solution:

-

Switched to 100% recycled 6061-R

-

Implemented nesting software to optimize blank usage

-

Partnered with closed-loop recycler for chips

Results: -

41% lower CO2 footprint

-

Scrap reduced to 9%

-

Material costs down 17%

Conclusion

Sustainable CNC machining isn’t just eco-friendly—it’s economically smart. By choosing materials like recycled aluminum, PHA biopolymers, and bamboo composites, manufacturers can cut costs, appeal to green-conscious clients, and future-proof operations.

Ready to switch to sustainable materials? Request a free material assessment from our experts!