Introduction: The Dawn of Intelligent Manufacturing

In today’s rapidly evolving manufacturing landscape, Industry 4.0 represents nothing short of a revolution—a fundamental transformation that’s reshaping CNC machining from a traditional craft into an intelligent, data-driven science. This fourth industrial revolution moves beyond automation to create cyber-physical systems where machines, components, and people communicate seamlessly through the Internet of Things (IoT).

The statistics speak volumes: The global smart manufacturing market is projected to reach $658.4 billion by 2029, growing at a CAGR of 12.4%, with CNC machining at the forefront of this transformation. Manufacturers implementing Industry 4.0 technologies report 20-30% gains in equipment effectiveness and 15-20% reductions in maintenance costs.

But what does this mean for your CNC operations? This comprehensive guide explores how Industry 4.0 technologies are creating smarter, more efficient, and more profitable machining environments—and how you can leverage these advancements to stay competitive in an increasingly digital world.

Understanding Industry 4.0 in the CNC Context

Industry 4.0 represents the convergence of physical production with digital technology. It’s characterized by nine key pillars, each playing a crucial role in modern CNC machining:

-

Big Data and Analytics

-

Autonomous Robots

-

Simulation/Digital Twins

-

Horizontal and Vertical System Integration

-

Industrial Internet of Things (IIoT)

-

Cybersecurity

-

The Cloud

-

Additive Manufacturing

-

Augmented Reality

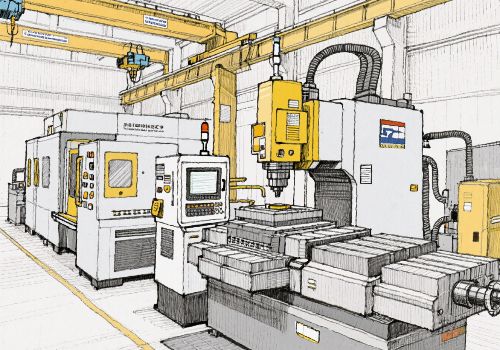

For CNC machining specifically, these technologies combine to create what many call the “smart factory”—where machines communicate with each other, self-optimize in real-time, and require minimal human intervention for routine operations.

The Transformative Technologies Reshaping CNC Machining

1. IoT and Machine Connectivity: The Nervous System of Smart Manufacturing

The Industrial Internet of Things (IIoT) forms the foundation of Industry 4.0 in CNC machining. By embedding sensors in machines, tools, and even workpieces, manufacturers gain unprecedented visibility into their operations.

Real-World Implementation:

-

Vibration sensors detect abnormal patterns indicating potential tool failure

-

Thermal sensors monitor spindle health and prevent thermal deformation

-

Power consumption monitors optimize energy usage and detect inefficiencies

-

RFID chips track tools and materials throughout the facility

Impact: One automotive manufacturer implemented IIoT sensors across their CNC fleet and achieved a 47% reduction in unplanned downtime and 22% longer tool life through predictive maintenance.

2. AI and Machine Learning: The Brain Behind the Operation

Artificial intelligence transforms raw data from IoT sensors into actionable intelligence. Machine learning algorithms analyze historical and real-time data to optimize machining processes autonomously.

Key Applications:

-

Adaptive Control: Systems automatically adjust feeds, speeds, and depth of cut based on real-time tool wear and material variations

-

Predictive Maintenance: AI models forecast equipment failures with 85-90% accuracy, allowing maintenance to be scheduled during planned downtime

-

Quality Prediction: Algorithms identify patterns that lead to defects before they occur

-

Process Optimization: Systems continuously refine machining parameters for maximum efficiency

Case Study: A medical device manufacturer implemented AI-driven adaptive control for machining titanium implants, reducing cycle times by 18% while improving surface finish quality by 31%.

3. Digital Twins: Virtual Replicas, Real Results

Digital twin technology creates a virtual replica of physical CNC machines, processes, or entire production lines. This allows manufacturers to simulate, test, and optimize operations in a risk-free digital environment.

Transformative Benefits:

-

Virtual Commissioning: Test new CNC programs without interrupting production

-

Process Optimization: Identify bottlenecks and optimize workflows before implementation

-

Predictive Analysis: Simulate how equipment will perform under different conditions

-

Training: Operators can learn on virtual machines without risking damage to physical equipment

Impact: Companies using digital twins report 40% faster commissioning of new machines and 25% fewer collisions and programming errors.

4. Additive and Hybrid Manufacturing: Blending Traditions

Industry 4.0 blurs the lines between additive and subtractive manufacturing. Hybrid machines that combine 3D printing with CNC machining are becoming increasingly common, allowing for complex geometries that would be impossible with either technology alone.

Applications:

-

Repair and Modification: Add material to existing components then machine to precise tolerances

-

Complex Geometries: Build internal channels and lattice structures then finish with precision machining

-

Custom Tooling: Rapidly produce custom fixtures and workholding devices

5. Advanced Robotics and Automation: The 24/7 Workforce

Collaborative robots (cobots) work alongside human operators to handle loading, unloading, and inspection tasks. Unlike traditional industrial robots, cobots are designed to operate safely alongside human workers without extensive safety cages.

Implementation Benefits:

-

Lights-Out Manufacturing: Extended unmanned production shifts

-

Consistent Quality: Elimination of human error in repetitive tasks

-

Enhanced Safety: Removal of workers from hazardous or ergonomically challenging tasks

-

Labor Optimization: Skilled technicians focus on higher-value activities

The Tangible Benefits: What Industry 4.0 Delivers to Your Shop Floor

Dramatic Efficiency Gains

-

Overall Equipment Effectiveness (OEE) improvements of 15-25%

-

Setup time reductions of 30-50% through digital workflows

-

Machine utilization rates increasing from industry average of 35% to 70% or higher

Unprecedented Quality Control

-

Real-time SPC (Statistical Process Control) with immediate feedback

-

Closed-loop machining where inspection data automatically updates tool offsets

-

100% part traceability throughout the manufacturing process

Enhanced Flexibility and Customization

-

Rapid changeovers between jobs through digital work instructions

-

Mass customization capabilities at near-mass-production costs

-

Faster response to engineering changes and design iterations

Sustainable Manufacturing

-

Energy consumption optimization through smart power management

-

Material waste reduction through improved process control

-

Extended tool life through optimal usage parameters

Implementation Roadmap: Transitioning to Industry 4.0

Phase 1: Foundation (0-6 Months)

-

Conduct technology audit and identify quick-win opportunities

-

Implement basic machine monitoring and data collection

-

Establish cybersecurity protocols

-

Train staff on Industry 4.0 concepts and benefits

Phase 2: Integration (6-18 Months)

-

Deploy advanced sensors and IoT infrastructure

-

Implement cloud-based data analytics platforms

-

Develop digital twins for critical processes

-

Introduce collaborative robotics for repetitive tasks

Phase 3: Optimization (18-36 Months)

-

Deploy AI and machine learning for predictive analytics

-

Implement fully integrated digital thread across operations

-

Develop autonomous decision-making capabilities

-

Continuous improvement through advanced analytics

Overcoming Implementation Challenges

Cultural Resistance

Solution: Involve operators early in the process, demonstrate tangible benefits, and provide comprehensive training to build confidence with new technologies.

Data Overload

Solution: Start with clearly defined Key Performance Indicators (KPIs) and focus on collecting data that directly impacts those metrics.

Integration Complexity

Solution: Work with technology partners who offer compatible systems and prioritize open architecture solutions that enable future expansion.

Cybersecurity Concerns

Solution: Implement defense-in-depth security strategies, regular vulnerability assessments, and employee security awareness training.

The Future Horizon: What’s Next for CNC Machining?

Industry 4.0 continues to evolve, with several emerging technologies set to further transform CNC machining:

-

5G Connectivity: Ultra-reliable, low-latency communication enabling real-time control of distributed manufacturing networks

-

Edge Computing: Processing data closer to the source for faster response times and reduced bandwidth requirements

-

Blockchain: Secure, transparent supply chain management and quality verification

-

Generative Design AI: Systems that automatically create optimal part designs based on performance requirements and manufacturing constraints

Conclusion: Your Competitive Advantage in the Digital Age

Industry 4.0 is not a distant future—it’s reshaping CNC machining today. The transition from isolated machines to interconnected, intelligent systems represents the most significant advancement in manufacturing since numerical control was first introduced.

The question is no longer whether to adopt Industry 4.0 technologies, but how quickly you can integrate them to maintain competitive advantage. Manufacturers who embrace this transformation are achieving unprecedented levels of efficiency, quality, and flexibility—while those who resist risk being left behind.

The journey toward smart manufacturing begins with a single step: assessing your current capabilities and identifying where digital technologies can deliver the most immediate value. Whether it’s implementing basic machine monitoring or developing comprehensive digital twins, each advancement moves you closer to the full potential of Industry 4.0.

Ready to transform your CNC operations? Contact Us for a personalized assessment of your digital maturity and a roadmap to smarter manufacturing.