The future of robotics in CNC machining is one of deep integration and intelligent collaboration, transforming standalone machines into self-optimizing, flexible manufacturing cells. We are moving beyond simple automation to a new era where robotics, empowered by AI, IoT, and digital twins, will drive unprecedented levels of efficiency, precision, and autonomy in workshops and factories.

Introduction: Beyond the Cage

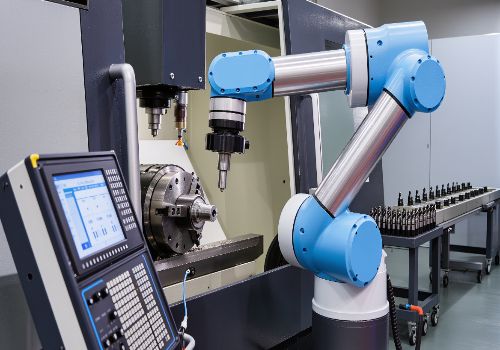

For decades, the image of a CNC machine often stood alone. The sight of a robotic arm, separated by a safety cage, performing repetitive loading and unloading tasks is familiar. While this automated loading was a significant first step, the true potential of robotics in CNC environments is only now being fully realized. The industry is on the cusp of a revolution where robotics is not just an accessory to the CNC machine but is becoming an integrated part of its intelligence and capability.

Fueled by advancements in artificial intelligence, sophisticated sensor technology, and seamless digital integration, robotics is set to redefine the very nature of precision manufacturing. This blog post explores the key trends and technologies that will shape the future of robotics in CNC machining, painting a picture of a smarter, more connected, and highly efficient factory floor.

The Evolution: From Automation to Autonomy

The journey of robotics in CNC machining has progressed through distinct phases:

-

Basic Automation: Simple, caged robots for high-volume, repetitive tasks like part loading and unloading.

-

Integrated Cells: Robots working in concert with multiple machines, often with basic sensing capabilities.

-

Intelligent Collaboration: The current and future state, where robots are cognitive collaborators. They can perceive their environment, make decisions, and adapt to variations in real-time, working alongside humans and machines with minimal intervention.

The global CNC robot market is projected to grow significantly, with one report forecasting a market value of $130.8 billion by 2031, advancing at a compound annual growth rate (CAGR) of 12.4% . This growth is a direct indicator of the technology’s increasing adoption and transformative potential.

Key Trends Shaping the Future

1. The Rise of “Machine Tool” Robotics

One of the most significant barriers to using robots for direct machining tasks like polishing, deburring, or milling has been their relative lack of path accuracy and stiffness compared to a dedicated 5-axis CNC machine. The future lies in bridging this gap.

Solution: SINUMERIK Machine Tool Robotics. Siemens has pioneered a solution that gives industrial robots the precision of a machine tool. By using a CNC controller (SINUMERIK ONE) to control the robot, this technology can improve path accuracy by 200-300% and significantly enhance dynamic stiffness .

Impact: This opens up new applications in aerospace and automotive for processing large components, like aircraft wings or car body molds, where a robot’s large work envelope is advantageous, but precision was previously insufficient. It also makes robots ideal for post-processing of 3D-printed metal parts, a task that is often time-consuming and labor-intensive.

2. AI and Machine Learning Become the “Brain”

Artificial Intelligence is the catalyst that will push robotic systems from automated to autonomous.

-

AI-Optimized Toolpaths: Companies like Aibuild are partnering with machine builders to use AI for generating optimized toolpaths for hybrid systems that combine additive manufacturing (3D printing) with CNC machining. The AI analyzes geometry and process parameters to synchronize material deposition and subsequent milling, reducing production times and material consumption .

-

Process Monitoring and Adaptive Control: With machine learning algorithms, robots can do more than just execute a program. They can learn from data. For example, an AI system can analyze sensor data during a grinding process to identify optimal pressure and speed, then adjust the robot’s actions in real-time for a perfect finish on every part .

-

Predictive Maintenance: AI-driven systems can monitor a robot’s own components—such as servo motors and reducers—predicting failures before they occur and scheduling maintenance to avoid unplanned downtime.

3. The Seamless Digital Thread: Digital Twins and IoT

The future CNC cell will be built first in a virtual world. Digital twin technology allows for the creation of a perfect virtual replica of the entire manufacturing process, including the robots, CNC machines, and workpieces .

-

Virtual Commissioning: Engineers can program, simulate, and test robotic CNC cells offline without interrupting production. They can validate cycle times, check for collisions, and optimize workflows long before physical implementation . Companies like FANUC use their DDMS digital twin system to virtually debug and optimize machining efficiency, slashing setup times .

-

IoT Integration: Robots will act as data hubs on the factory floor. Equipped with a suite of sensors (force, vision, laser displacement), they will feed real-time performance data into a central platform. This creates a closed-loop system where the physical process continuously informs and optimizes the digital plan . As noted in industry analysis, this IoT integration is making CNC systems more reliable, economical, and sustainable.

4. Human-Robot Collaboration (Cobots) Expands

Collaborative robots (cobots) are designed to work safely alongside human operators without the need for extensive safety caging. In future CNC shops, their role will expand:

-

Assisting with Complex Setups: A human operator can guide a cobot through a complex path for a one-off part by hand, and the cobot can then remember and replicate that path with high precision.

-

Performing Value-Added Tasks: While the CNC machine runs, a cobot can be tasked with secondary in-process operations like inspection using built-in metrology tools or cleaning finished parts.

5. The Flexibility of Hybrid Manufacturing

The line between additive and subtractive manufacturing will continue to blur, and robots will be at the center of this convergence. Hybrid manufacturing cells, using a robot arm that can switch between a deposition head for 3D printing and a spindle for milling, offer ultimate flexibility . This allows for:

-

Repairing expensive components by adding material only where needed and then machining it to precise tolerances.

-

Creating complex geometries that are impossible with traditional machining alone.

Table: Comparison of Robot Types in Future CNC Applications

| Robot Type | Key Strengths | Ideal Future CNC Applications |

|---|---|---|

| Articulated Robot | High flexibility, large work envelope | Machine tending, welding, sealing, large-part polishing & deburring |

| Collaborative Robot (Cobot) | Safe human interaction, easy programming | Small-batch tending, assembly, light finishing tasks alongside operators |

| Machine Tool Robot (e.g., SINUMERIK) | High path accuracy, stiffness | Direct machining of large parts (aerospace), precision post-processing of 3D prints |

| Gantry/Cartesian Robot | High rigidity over very large areas | Handling very large, heavy parts between multiple massive CNC machines |

Real-World Applications Taking Shape Today

The future isn’t entirely theoretical; it’s being implemented now:

-

Aerospace: Intelligent robots are already machining complex surfaces on turbine blades, using real-time force feedback to ensure consistent quality and adapting to material inconsistencies .

-

Automotive: Manufacturers use robotic cells for the complete processing of engine blocks and transmission housings, performing milling, cleaning, and inspection in a single, unmanned cycle .

-

Job Shops: With solutions like Tezmaksan’s CubeBOX, even smaller manufacturers can implement lights-out production. This automated system can increase night-shift efficiency by 50%, significantly shortening the return on investment

Challenges on the Horizon

The path forward is not without obstacles:

-

High Initial Investment: The cost of advanced robotic systems remains a barrier, especially for SMEs .

-

Integration Complexity: Merging robotics, CNC, and software into a seamless system requires significant expertise .

-

Skills Gap: The industry needs a new kind of technician—one skilled in robotics programming, data analysis, and traditional machining

Conclusion: A Symbiotic Future

The future of robotics in CNC machining is not about replacing human ingenuity but about augmenting it. The vision is one of seamless synergy: where robots handle the repetitive, strenuous, and precise physical tasks, while AI and digital twins provide the predictive intelligence. This frees human experts to focus on higher-value activities like process design, innovation, and strategic problem-solving.

This transformation will lead to manufacturing that is not only faster and cheaper but also more agile, customizable, and resilient. For companies willing to invest and adapt, the integration of advanced robotics into CNC machining represents a powerful competitive advantage in the global market.

Is your manufacturing operation ready for the robotic revolution? To stay competitive, begin exploring how these technologies can be integrated into your long-term strategy. The factory of the future is being built today.