Introduction

Maximizing CNC machine utilization is critical for boosting productivity, reducing costs, and increasing ROI. Many shops operate at less than 60% utilization, leaving significant profit potential untapped.

In this comprehensive guide, we’ll explore proven strategies to optimize your CNC machine utilization, from smart scheduling to advanced automation techniques.

What is CNC Machine Utilization?

CNC machine utilization measures how effectively your machines are running productive work versus sitting idle. It’s calculated as:

Utilization % = (Productive Machine Time / Total Available Time) × 100

Top-performing shops achieve 85-95% utilization through careful optimization.

10 Strategies to Maximize CNC Machine Utilization

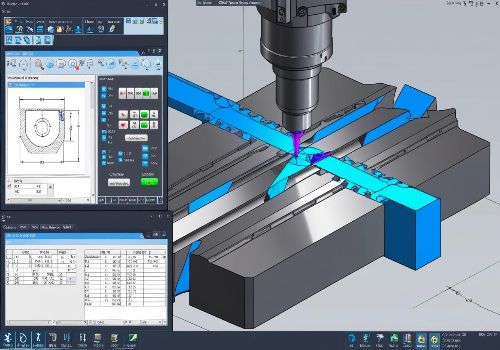

1. Implement Advanced Scheduling

-

Use AI-powered scheduling software to:

-

Minimize setup changes

-

Group similar jobs

-

Prioritize urgent orders

-

-

Example: Siemens Opcenter APS

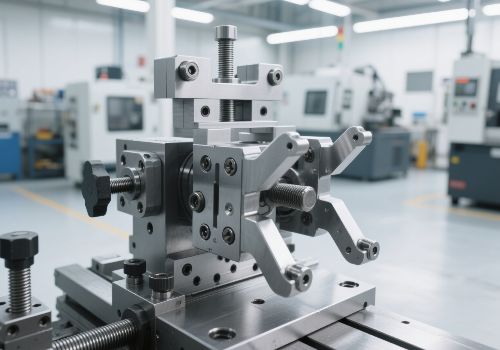

2. Reduce Setup Times

-

Apply SMED (Single-Minute Exchange of Die) principles:

-

Standardize tooling

-

Use quick-change fixtures

-

Prepare setups offline

-

3. Automate Tool Management

-

Install automatic tool changers (ATCs)

-

Use tool presetters to prepare tools offline

-

Implement RFID tool tracking

4. Adopt Lights-Out Manufacturing

-

Run unattended night shifts with:

-

Automatic pallet changers

-

Robotic part loading

-

Machine monitoring systems

-

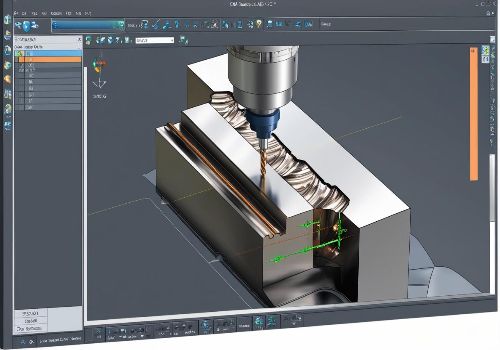

5. Optimize Cutting Parameters

-

Use adaptive toolpaths to reduce cycle times

-

Implement high-speed machining (HSM)

-

Apply trochoidal milling strategies

6. Improve Maintenance Practices

-

Follow predictive maintenance:

-

Vibration monitoring

-

Thermal imaging

-

Oil analysis

-

-

Reduce unplanned downtime

7. Upgrade to Multi-Tasking Machines

-

Invest in 5-axis or mill-turn machines to:

-

Complete parts in one setup

-

Eliminate secondary operations

-

Reduce handling time

-

8. Implement Lean Manufacturing

-

Apply 5S methodology:

-

Sort

-

Set in order

-

Shine

-

Standardize

-

Sustain

-

-

Reduce non-value-added activities

9. Use Machine Monitoring Systems

-

Install IoT sensors to track:

-

Spindle utilization

-

Cycle times

-

Downtime causes

-

-

Example: MachineMetrics, Seiki

10. Cross-Train Operators

-

Develop flexible workforce that can:

-

Run multiple machines

-

Perform setups

-

Handle basic maintenance

-

Key Performance Indicators (KPIs) to Track

| KPI | Target | Measurement Method |

|---|---|---|

| Machine Utilization | >85% | Monitoring software |

| OEE (Overall Equipment Effectiveness) | >80% | (Availability × Performance × Quality) |

| Setup Time | <15 min | Time studies |

| Mean Time Between Failures (MTBF) | Maximize | Maintenance logs |

Common Utilization Killers & Solutions

| Problem | Solution |

|---|---|

| Excessive setups | Implement quick-change systems |

| Tool breakage | Use tool condition monitoring |

| Material shortages | Improve inventory management |

| Operator dependency | Automate loading/unloading |

Technology Enablers for Higher Utilization

✔ Digital twins – Virtual machine optimization

✔ Edge computing – Real-time process adjustments

✔ Collaborative robots – Flexible automation

✔ Cloud-based analytics – Performance insights

Conclusion

Optimizing CNC machine utilization requires a combination of smart processes, workforce training, and advanced technologies. By focusing on reducing setups, automating workflows, and eliminating downtime, manufacturers can significantly increase output without additional capital investment.

Need help boosting your machine utilization? Contact our experts for a free productivity assessment!