Introduction

CNC machining delivers high precision, but part movement during cutting can ruin accuracy, damage tools, and waste materials. Whether you’re working with metals, plastics, or composites, securing your workpiece is critical. In this guide, we’ll explore proven methods to prevent parts from shifting during CNC machining, ensuring flawless results every time.

Why Do CNC Machined Parts Move?

Before fixing the problem, it’s essential to understand why parts shift during machining:

-

Excessive cutting forces – Aggressive feeds/speeds can dislodge workpieces.

-

Poor workholding – Weak clamps, incorrect fixtures, or improper vise use.

-

Vibration & chatter – Unstable setups lead to movement over time.

-

Thermal expansion – Heat from machining can warp thin or delicate materials.

-

Chip buildup – Accumulated chips can lift or misalign parts.

Best Ways to Prevent Part Movement in CNC Machining

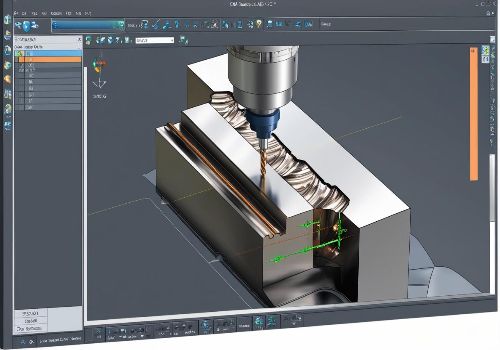

1. Use the Right Workholding Method

Choosing the correct workholding solution is the first step in preventing movement. Common options include:

-

CNC Vises – Ideal for milling, with soft jaws for custom grips.

-

Clamps & Step Clamps – Best for irregular or large parts.

-

Vacuum Tables – Excellent for thin sheets and non-porous materials.

-

Magnetic Chucks – Used for ferrous metals in grinding and milling.

-

T-Slot Tables – Allow flexible clamping setups.

Pro Tip: Always ensure clamps apply even pressure to avoid distortion.

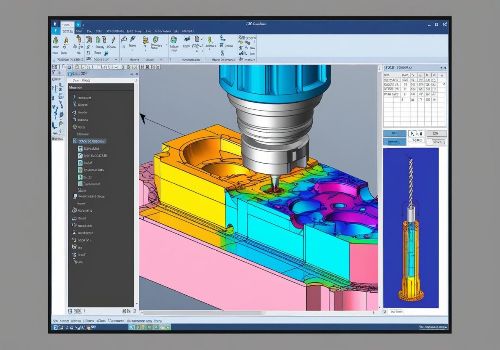

2. Optimize Cutting Parameters

Too much force can dislodge parts. Adjust:

-

Feed rate – Reduce if parts vibrate or shift.

-

Spindle speed – Higher RPM may reduce cutting forces.

-

Depth of cut – Lighter passes minimize stress on the workpiece.

3. Use Proper Fixturing for Complex Parts

For irregular shapes, custom fixtures ensure stability:

-

Soft Jaws – Machined to match the part’s contour.

-

Modular Fixtures – Adjustable for different geometries.

-

Pneumatic & Hydraulic Clamps – Provide consistent pressure.

4. Minimize Vibration & Chatter

Vibration loosens workpieces. Solutions include:

-

Dampening Pads – Absorb machine vibrations.

-

Balanced Toolholders – Reduce harmonic distortion.

-

Stiffer Tooling – Short, thick end mills resist deflection.

5. Keep the Work Area Clean

Chip buildup can lift parts or interfere with clamping:

-

Use Air Blasts or Coolant – Clear chips during machining.

-

Regularly Clean Vises & Fixtures – Prevent debris from causing misalignment.

6. Add Support for Thin or Weak Materials

Flexible materials (e.g., aluminum sheets, plastics) need extra support:

-

Backing Plates – Reinforce thin parts.

-

Adhesive Pads – Temporary bonding for delicate workpieces.

-

Vacuum Pallets – Hold lightweight materials securely.

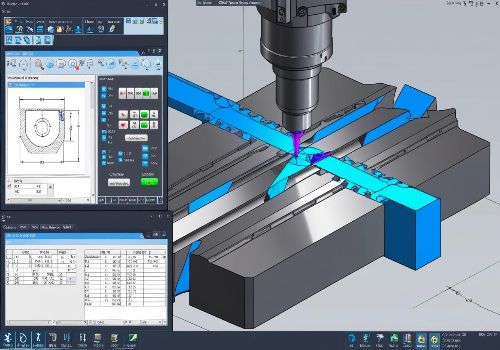

7. Verify Setup Before Machining

A quick check prevents costly errors:

-

Test Run (Dry Run) – Confirm no collisions or movement.

-

Indicator Check – Ensure the workpiece hasn’t shifted.

-

Torque Check – Tighten clamps to manufacturer specs.

Common Mistakes to Avoid

-

Over-tightening clamps – Can deform the part.

-

Insufficient contact area – Leads to slippage.

-

Ignoring thermal effects – Heat expansion changes tolerances.

-

Using worn-out tooling – Increases cutting forces.

Conclusion

Preventing part movement in CNC machining requires proper workholding, optimized cutting parameters, and vibration control. By using the right fixtures, maintaining a clean workspace, and verifying setups, you can achieve high precision and repeatability in every job.

Need expert CNC machining services with guaranteed stability? Contact us today for reliable, high-quality parts!