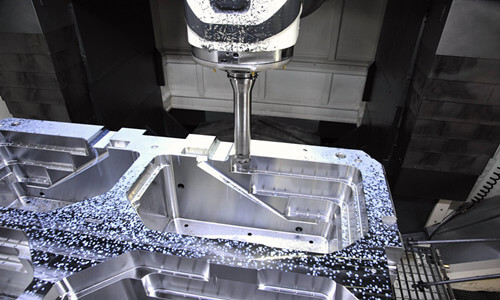

CNC machining is the most widely used machining method at present, and it is also the basic skill that every machining worker must master. After the start-up, workpiece clamping, workpiece hit count, preparation tool and processing parameters are set, it enters the start-up process. In this process, what precautions need to be noticed by the operator, we will carry out a relevant summary.

Tool and feed rate

All tools must be carefully checked before starting each program to ensure that the tools match the tools specified in the programming instructions. At the beginning of processing, the feed rate should be minimized. The method of single-section execution, rapid positioning, and knife-cutting must be used. Attention should be paid when entering the knife, and the hand should be placed on the stop button. If the problem is found, it must be immediately stop. During the machining process, pay attention to the direction of the tool to ensure a safe feed, then slowly increase the feed rate until the appropriate value is reached, and add coolant or cold air to the tool and workpiece to reduce the cutting temperature.

Open roughing precautions

When roughing the workpiece, the position of the operator should not be too far from the control panel. This ensures that the machine can be shut down in time if it encounters an abnormal phenomenon. After the roughing, pull the table again to make sure that the workpiece is not loose. If there is any, the workpiece must be recalibrated. In processing, the processing parameters should be continuously optimized according to the processing conditions to achieve the best results.

Because roughing is a very critical process, after processing, the main dimension value should be measured to see if it is consistent with drawing requirements. After self-inspection, it can be removed and must be sent to the inspector for special inspection.

Drilling processing precautions

Performing drilling on a machining center is a three-step process. First, the center drill must be used to position the hole, then drilled with a drill bit that is 0.5 to 2 mm smaller than the hole size of the drawing, and finally finished with a suitable bit.

Reaming processing precautions

Similar to drilling, the reaming of the workpiece is also divided into three steps. First, the hole is to be positioned with the center drill, and then drilled with a drill bit smaller than the aperture size of the drawing by 0.5 to 3 mm, and finally the reamer is used. When reaming, be careful to control the spindle speed within 70 to 180 rpm, neither lower than the lower limit nor higher than the upper limit.

Boring processing precautions

The boring of the workpiece is divided into four steps. The first step is to locate with a center drill. The second step is to drill with a drill bit that is 1 to 2 mm smaller than the hole size of the drawing. The third step is to use a rough boring tool or a milling cutter to processing to a machining allowance of only about 0.3 mm on one side, the last step is to use a precision boring tool with a pre-adjusted size for fine boring. The fine balance should not be less than 0.1 mm.