Introduction

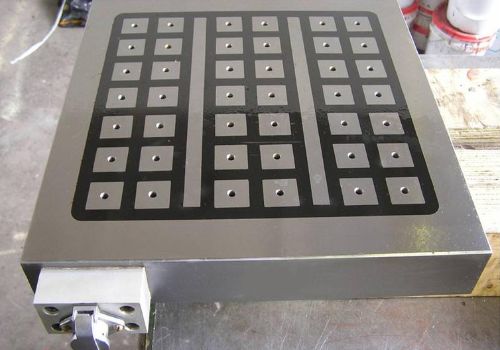

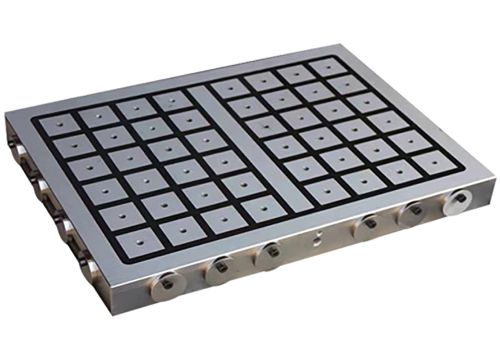

Magnetic workholding is a popular solution in CNC machining, grinding, and milling operations, offering fast setup times and secure clamping for ferrous metals. Unlike traditional mechanical vises or clamps, magnetic chucks use electromagnetic or permanent magnet technology to hold workpieces firmly in place.

But is magnetic workholding right for your application? In this guide, we’ll break down the key pros and cons to help you decide.

How Magnetic Workholding Works

Magnetic workholding systems come in two main types:

-

Electromagnetic Chucks – Use electric current to generate a magnetic field (adjustable strength).

-

Permanent Magnetic Chucks – Use fixed magnets (no power required, manual activation).

Both types provide strong holding force for steel, iron, and other ferromagnetic materials but are ineffective on non-magnetic metals like aluminum, brass, or titanium.

Pros of Magnetic Workholding

✅ 1. Fast Setup & Changeover

-

No mechanical clamps or vises needed—just place the part and activate the magnet.

-

Ideal for high-volume production where speed matters.

✅ 2. Full Workpiece Access

-

Unlike vises or clamps, magnetic chucks don’t obstruct machining surfaces.

-

Allows 5-axis machining without interference.

✅ 3. No Part Distortion

-

Mechanical clamping can bend thin or delicate parts—magnets apply even pressure without deformation.

-

Best for precision grinding and fine finishing.

✅ 4. Low Maintenance

-

No moving parts to wear out (unlike mechanical fixtures).

-

Permanent magnet chucks require no electricity.

✅ 5. Improved Chip Evacuation

-

Open workholding design lets chips fall away easily, reducing recutting and tool wear.

Cons of Magnetic Workholding

❌ 1. Only Works on Ferrous Metals

-

Cannot hold aluminum, copper, plastics, or composites (non-magnetic materials).

-

Some stainless steels (e.g., 300 series) have weak magnetic properties.

❌ 2. Limited Holding Force for Heavy Cuts

-

Aggressive machining may cause part slippage under extreme forces.

-

Not ideal for roughing operations with high tool pressure.

❌ 3. Heat Sensitivity

-

High temperatures (e.g., welding or heavy grinding) can weaken magnetic force.

-

Electromagnetic chucks may lose power if overheated.

❌ 4. Residual Magnetism Concerns

-

Some parts retain slight magnetism after removal, which may affect electronic components.

-

Requires demagnetizing tools for sensitive applications.

❌ 5. Higher Initial Cost

-

Magnetic chucks are more expensive than basic vises or clamps.

-

Electromagnetic systems need a power supply and controls.

Best Applications for Magnetic Workholding

✔ Surface & Cylindrical Grinding – High-precision finishes

✔ EDM Machining – Secure holding without vibration

✔ Thin-Walled Part Machining – Prevents distortion

✔ 5-Axis Milling – Unobstructed access to all sides

When to Avoid Magnetic Workholding

✖ Non-ferrous materials (aluminum, brass, titanium)

✖ Heavy roughing operations (high cutting forces)

✖ Extreme heat environments (can weaken magnetism)

Conclusion

Magnetic workholding offers speed, precision, and flexibility for ferrous metal machining but has limitations with non-magnetic materials and heavy cutting. If your work involves grinding, finishing, or thin-part machining, it’s an excellent choice. For high-force roughing or non-ferrous metals, traditional clamping may be better.

Need help selecting the right workholding solution? Contact our experts today for personalized advice!