Introduction

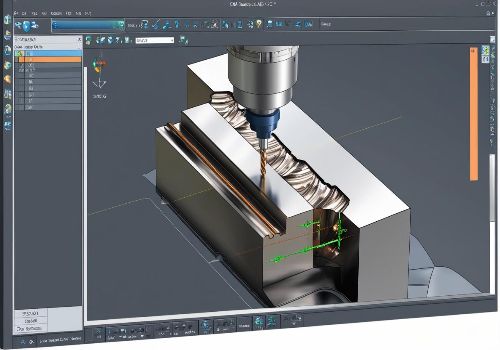

CNC machining is one of the most accurate and efficient methods for creating functional prototypes. Unlike 3D printing, CNC prototypes offer real-material properties and tight tolerances (±0.005″ or better) for testing fit, form, and function.

But prototyping has unique challenges—fast turnaround, design changes, and cost control are critical. In this guide, we’ll break down the best CNC practices for prototyping, from design optimization to machining strategies.

Top 10 CNC Prototyping Best Practices

1. Design for Manufacturability (DFM) Early

-

Avoid undercuts & deep cavities that require special tooling

-

Use standard tool sizes (e.g., avoid 0.3mm holes unless critical)

-

Add draft angles for easier milling

2. Choose the Right Material

| Material | Best For | Considerations |

|---|---|---|

| 6061 Aluminum | General prototyping | Easy to machine, cost-effective |

| Delrin (POM) | Low-friction parts | No coolant needed |

| ABS | Functional testing | Can warp if machined thin |

| Brass | Precision components | Excellent machinability |

3. Use Soft Jaws for Quick Iterations

-

Machine custom jaws to hold irregular shapes

-

Allows fast design changes without new fixtures

4. Optimize Toolpaths for Speed

-

Adaptive Clearing – Removes material faster

-

Trochoidal Milling – Reduces tool wear

-

Rest Machining – Only cuts remaining stock

5. Leverage 3D Printing for Fixtures

-

3D-printed jigs reduce machining time

-

Ideal for one-off prototype holders

6. Implement High-Speed Machining (HSM)

-

Higher RPM + lighter cuts = better surface finish

-

Reduces cycle times by 20-40%

7. Skip Finishing Passes (When Possible)

-

For fit-check prototypes, roughing may be sufficient

-

Saves 30-50% machining time

8. Use Probing for Critical Features

-

On-machine probes verify dimensions without CMM

-

Adjusts offsets automatically if errors are detected

9. Document Everything

-

Record speeds/feeds, tooling, and setup notes

-

Makes design revisions 10x faster

10. Partner with a Prototype-Specialized Shop

-

Look for shops with:

✔ Quick-turn capabilities (3-5 day lead times)

✔ Small-batch expertise

✔ Design-for-machining feedback

Prototyping vs. Production: Key Differences

| Factor | Prototyping | Production |

|---|---|---|

| Tolerances | ±0.010″ (unless critical) | ±0.005″ or tighter |

| Material | Often aluminum or plastics | Final-use materials |

| Toolpaths | Optimized for speed | Optimized for tool life |

| Finishing | As-machined often acceptable | Polished/anodized |

Common Prototyping Mistakes to Avoid

❌ Over-dimensioning – Only specify critical tolerances

❌ Ignoring tool access – Can’t machine what tools can’t reach

❌ Using production processes – Wastes time/money

❌ Skipping DFM review – Leads to unmanufacturable designs

Case Study: Drone Arm Bracket Prototype

Challenge: Needed 5 design iterations in 2 weeks

Solutions:

-

Used aluminum + soft jaws for fast changes

-

HSM toolpaths cut machining time by 35%

-

Probing ensured motor mount accuracy

Result: Finalized design in 11 days (vs. 4 weeks with 3D printing)

Conclusion

CNC prototyping shines when you balance speed, cost, and functionality. By focusing on DFM, smart toolpaths, and the right partnerships, engineers can iterate faster and avoid costly redesigns.

Need rapid CNC prototypes? Get an instant quote with our 5-day turnaround guarantee!