Introduction

High scrap rates silently drain profits in CNC shops—wasting material, time, and machine capacity. The average machine shop loses 5-20% of production to scrap and rework, but top-performing manufacturers achieve <2% scrap rates through systematic optimization.

In this guide, we’ll reveal proven strategies to minimize scrap in CNC machining, covering tooling, programming, quality control, and process optimization.

Top Causes of CNC Scrap (And How to Fix Them)

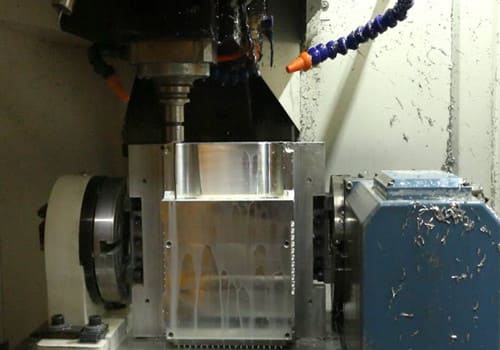

1. Poor Workholding & Part Movement

Problem: Parts shift during machining, causing dimensional errors.

Solutions:

✔ Use custom soft jaws for better grip

✔ Implement hydraulic/pneumatic clamping for consistency

✔ Add anti-vibration pads for thin-walled parts

2. Incorrect Cutting Parameters

Problem: Wrong speeds/feeds cause tool breakage or poor finishes.

Solutions:

✔ Use adaptive toolpaths to maintain optimal chip load

✔ Follow tool manufacturer’s recommendations

✔ Implement tool wear monitoring

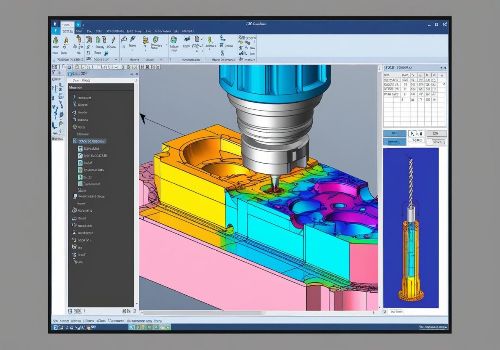

3. Programming Errors

Problem: CAM mistakes lead to crashes or wrong dimensions.

Solutions:

✔ Always simulate programs before running

✔ Use proven post-processors

✔ Apply in-process probing to verify critical features

4. Material Defects

Problem: Voids or inconsistent stock cause unexpected failures.

Solutions:

✔ Source certified materials from reputable suppliers

✔ Perform ultrasonic testing on critical blanks

✔ Use probe cycles to check stock before machining

5. Tool Wear & Breakage

Problem: Dull or broken tools produce out-of-tolerance parts.

Solutions:

✔ Set up tool life management in your CNC

✔ Use coated tools for longer life

✔ Implement automatic tool changers (ATCs)

6 Advanced Strategies to Reduce Scrap

1. Statistical Process Control (SPC)

-

Track key dimensions with real-time SPC software

-

Detect trends before parts go out of tolerance

2. Lights-Out Machining with In-Process Inspection

-

Use on-machine probes to measure parts mid-cycle

-

Automatically adjust offsets if drift occurs

3. Standardized Setup Procedures

-

Create checklists for fixturing and tool offsets

-

Use set-up sheets with photos to reduce human error

4. First-Article Inspection (FAI) Protocols

-

Fully inspect first part before running batch

-

Verify with CMM or optical comparators

5. Employee Training & Certification

-

Regular CNC programming workshops

-

Cross-train operators on quality standards

6. Predictive Maintenance

-

Monitor spindle vibration, temperature, and load

-

Replace components before they fail catastrophically

Scrap Reduction ROI Calculator

| Action | Scrap Reduction | Annual Savings* |

|---|---|---|

| Improve workholding | 30% | $18,000 |

| Implement tool monitoring | 25% | $15,000 |

| Add in-process probing | 40% | $24,000 |

| *Based on average shop with $200k annual scrap costs |

Case Study: Aerospace Supplier Cuts Scrap by 68%

Challenge: 11% scrap rate on titanium aircraft components

Solutions Implemented:

-

Switched to high-pressure coolant system

-

Added laser tool breakage detection

-

Implemented automated post-machining inspection

Results: Scrap reduced to 3.5% in 6 months

Conclusion

Minimizing scrap requires a systematic approach—from robust workholding to smart quality control. By addressing the root causes of waste and leveraging technologies like in-process probing and SPC, manufacturers can dramatically improve yields and profitability.

Need help reducing your scrap rates? Request a free machining audit from our engineering team!