Many entrepreneurs want to invest in the project of opening a mechanical processing plant. The advantage of opening a mechanical processing plant is that the investment cost is small, the return is fast, the operation and management is simple, etc., but some people find it too difficult to open a mechanical processing plant? Here are a few cost-saving techniques for reference.

1. Reduce ineffective power consumption

A. Electricity for lighting: turn off the lights before leaving; when a small number of people work, only provide lighting for the work area, avoiding a small number of people from consuming a large area of lighting.

B. Air-conditioning power: office air-conditioning is controlled in separate rooms to reduce use time and unnecessary air-conditioning power; air conditioning should be turned off at noon.

C. Projector power: turn off the power after the product is measured; during interval measurement, if the interval exceeds half an hour, the power should be turned off, and it is not allowed to turn on the power for a long time without using it.

D. Copier and water dispenser power: turn off the power after copying; during interval measurement, if the interval exceeds half an hour, the power should be turned off, and it is not allowed to turn on the power for a long time without being used.

2. Reduce material loss

A. Do not allow small materials to fall on the ground and ignore them. Violators shall be punished according to craft discipline.

B. Damaged materials are not allowed. Whoever damages will compensate and whoever will bear the responsibility.

C. For the material loss caused by poor incoming materials, screening or rework in the workshop, the workshop should clarify the responsibility in time and deal with it in time after the quality supervisor confirms it.

D. The materials in the workshop shall be cleared daily. In principle, the damaged materials that appear on the day will be processed on the same day, and the workshop shall not allow any dull materials.

3. Reduce invalid working hours

A. Reasonably standardize the layout of the workshop to shorten the internal logistics of the workshop and reduce the number of handling.

B. Reasonably standardize the positioning of materials and tools at work stations.

C. The workshop strictly implements the process discipline to reduce the defect rate and reduce maintenance man-hours.

D. The workshop has a good daily plan and production billboard to reduce the time for line replacement.

E. The production department arranges the production plan reasonably. When the task order is not full, it should arrange one or two days off to effectively control the indirect working hours.

F. The quality department strictly controls the quality of incoming materials, reduces the entry of poor-quality materials into the workshop, and reduces the processing time for poor-quality materials.

4. Reduce manpower consumption

A. The production department ensures the accuracy of the production plan. Accurately plan the manpower requirements of the workshop, and achieve reasonable manpower allocation.

B. The production department shall ensure the balance of the daily production plan based on the working hour quota.

C. The workshop should use manpower reasonably and implement the daily production plan effectively according to the daily production plan and working hours quota. Reduce unnecessary overtime and reduce the manpower loss caused by insufficient work.

5. Reduce the loss of production auxiliary supplies

A. The production department should control the distribution of auxiliary supplies and carefully complete the accounting and approval procedures.

B. The production, quality and other departments strengthen the control of copy paper, forms and other supplies to minimize unnecessary losses.

Entrepreneurs should pay attention to the level of craftsmanship, improve the quality of products, and understand the actual needs of customers when they open mechanical processing plant. I hope that the above points will help everyone.

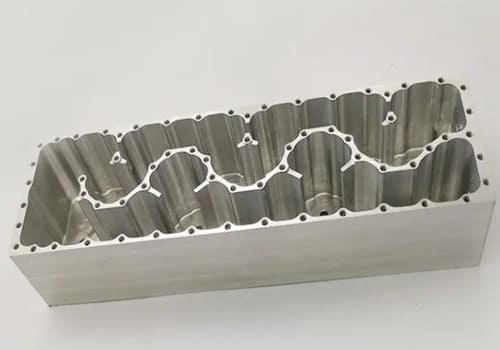

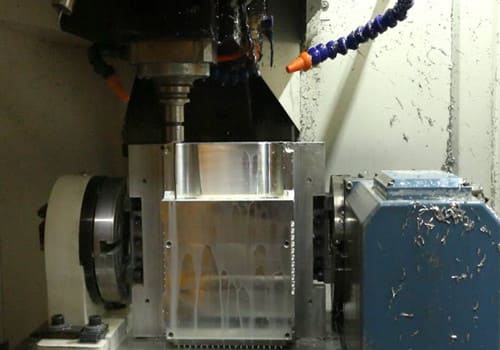

As a professional CNC machining manufacturer, DO Machining not only produce metal parts, but plastic and wood parts are also available.

Please visit our CAPABILITIES and what PRODUCTS we did.

CNC machining service is the core business of DO Machining, from protptyes to bulk production, our professional 3/4/5 aixs CNC machining centers, CNC turning equipments, CNC turning-milling equipments, CNC grinding machines etc., are operated by well trained manufacturing engineers to meet the demands from global 1000+ customers in 30+ industries.

CNC Machining can be done starting with blanks produced from standard bar stock or one of DO Machining other manufacturing processes.

Contact us to see how we can provide overall value to your CNC machining needs.