When it comes to surface treatment, many people always think of metal surface treatment. In fact, plastics can also be surface treated.

The surface treatment of plastic is to form a surface layer with some or more special properties on the surface of the material by physical or chemical methods. It can improve the performance of product appearance, texture, function and other aspects.

Then, what are the surface treatment processes for plastics?

There are many common plastic surface treatment methods, among which electroplating and painting are more common methods. The following is a comprehensive introduction to the plastic surface treatment process:

1. Frosting

Frosted plastic generally refers to plastic film or sheet. When extruding the sheet, there is a frost pattern on the surface of the forming roller, so that the frost pattern is naturally formed during the cooling of the plastic. This method is simple and fast, especially for transparent products have a better results.

2. Polishing

Use mechanical, chemical or electrochemical effects to reduce the surface roughness of the workpiece to obtain a bright and smooth surface. Plastic products are generally polished with rolled-up sandpaper, which is usually the previous step of spraying.

3. Spraying

Plastic spraying is mainly to coat a layer of plastic paint on plastic products, and then perform a drying operation, usually about 10 minutes. Spray paint will cut off the air, can play a role in anti-aging plastic products, the most important thing is to get the appearance effect that plastic product itself do not have.

4. Silk screenprinting

The screen printing stencil is usually square and has a fine mesh shape. During printing, the ink on the screen printing stencil is leaked from the through hole of the stencil surface to the substrate under the pressure of the squeegee. If PC adopts this kind of surface treatment, the effect is very good

5. Pad printing

First etch the designed pattern on the printing plate, coat the etching plate with ink, and then transfer most of the ink to the printed object through the silicone head.

6. Thermal transfer

The pattern is printed on the surface of the transfer film in advance, and the pattern on the transfer film is transferred to the product surface by one-time processing (heating and pressing) by a thermal transfer machine. After molding, the ink layer and the surface of the product are integrated, which is realistic and beautiful. Which greatly improve the grade of the product.

7. Water transfer

It is a kind of printing that uses water pressure to hydrolyze the transfer paper/plastic film with color patterns.

8. Laser engrave

Use the energy of the laser to process the surface into a “trace”, exposing a layer of material below the outer surface, it can engrave letter or pattern as needed.

9. Electrophoresis

One of the metal electrodeposition techniques, usually a metal coating process that uses chromium, zinc and other metals to obtain a deposited layer on the surface of the workpiece through an electrochemical reaction. Make the outside of the plastic parts have a metallic texture, and make the material resistant to corrosion and wear. The common plastic materials in this surface treatment process are ABS and PC.

10. Vacuum coating

The atoms of the material in the vacuum chamber are separated from the heating source and hit the surface of the object to be coated. This method can obtain a dazzling effect and is suitable for ABS and PC plastic products.

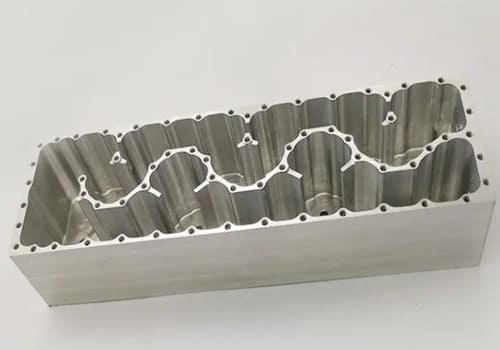

As a professional CNC machining manufacturer, DO Machining not only produce metal parts, but plastic and wood parts are also available.

Please visit what MATERIALS and what SURFACE FINISHES we can offer.

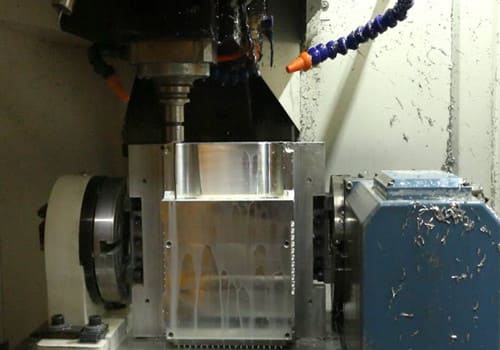

CNC machining service is the core business of DO Machining, from protptyes to bulk production, our professional 3/4/5 aixs CNC machining centers, CNC turning equipments, CNC turning-milling equipments, CNC grinding machines etc., are operated by well trained manufacturing engineers to meet the demands from global 1000+ customers in 30+ industries.

CNC Machining can be done starting with blanks produced from standard bar stock or one of DO Machining other manufacturing processes.

Contact us to see how we can provide overall value to your CNC machining needs.