How To Overcome Deformation In CNC Turning Thin Wall Parts?

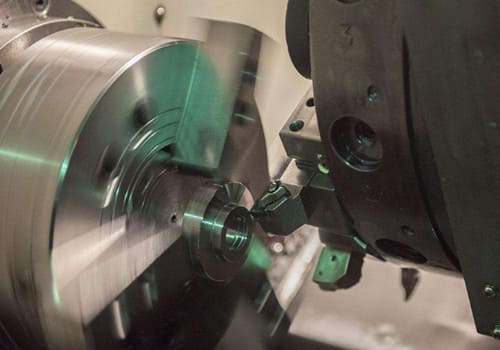

During the cutting process, the thin wall is easily deformed by the cutting force, resulting in the appearance of an ellipse, or the phenomenon that the middle is small and the two ends are large. In addition, due to the poor heat dissipation during processing, the thin-walled sleeve is easily thermally deformed, and it [...]